Metal Has Made It

Metal Has Made It

Aluminum ain’t just for Apple anymore. Here’s why metal prints have caught on as the new

medium of choice for paper warry photo printers.

1. Bonded to be bold.

The dye sublimation process fuses pigment directly into the surface of coated metal, creating

depth and intense color saturation. Archival inks heated to over 400 degrees are chemically

bonded to the surface so there is no adhesive or ink overlay to separate over time. Metal prints

are as archival as the finest silver- and ink-based photographs.

2. Aluminum is easy.

Because they’re aluminum, they’re only 1mm thick, yet very rigid. That makes small prints great

for any shelf or desktop display where they can be leaned or set in a slatted base.

Medium sizes like 12×12 and 20×20 look right at home as-is, on a mantle or shelf without any

additional finishing. And larger prints can be floated off the wall, mounted to other substrates, or

framed for stunning glass-less presentations that weight barely more than a mounted paper

photograph would.

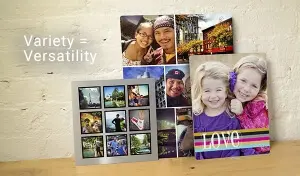

3. Variety = versatility.

Metal prints fit every environment. The large and custom size options are well suited for

commercial applications like offices and corporate boardrooms. They’re the first choice for

medical or industrial environments that require sterility or infallibility in cold, hot, or humid

environments. And the tough, durable properties of aluminum make them particularly applicable

to tamper-proof and touch-friendly installations like museums and municipalities.

All this in a print with fine-art quality and long life. What will you make with metal?